Manufacturing

Easily track production stages, equipment maintenance records, & more in your manufacturing facility.

Manufacturing systems receive extensive benefits from capturing and analyzing all the aspects of their systems, procedures and equipment usage data. Here’s how Slate Pages can be used in a manufacturing setting.

Production:

- Production tracking (stages)

- Equipment maintenance

- QA QC (quality assurance / quality control)

- Inventory management

Big picture:

- Incorporating with other systems

- Scheduling / Production planning

- Recourse management (people and assets)

End users:

- Asset Information (make, model, serial number, etc…)

- Manuals

- Maintenance instructions and checklist

- Warranty tracking

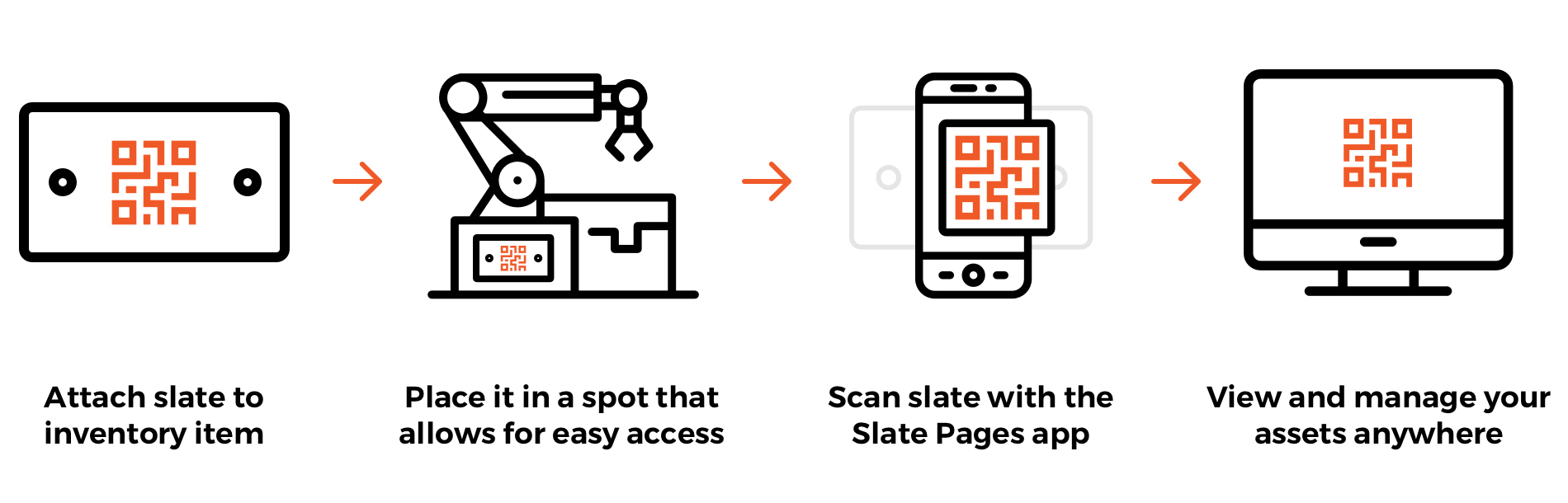

Slate Pages is the best tool for tracking & managing manufacturing. Here’s how it works:

How Slate Pages helps Thermaxx manufacture mechanical insulation

Slate Pages is integrated into every step of Thermaxx’s custom mechanical insulation manufacturing procedures. It all starts before the manufacturing begins. Stacks are created to represent jobs and each Slate QR code represents a product that is being manufactured. Field technicians are dispatched to a job site to capture detailed information about the asset being insulated along with measurements and photos. This critical information, including measurements and photos, are uploaded to each individual Slate. Paper checklists and measurement instructions are digitized and stored with the Slate Page app.

Insulation designers pull this information from the Slate and create a detailed CAD drawing. These CAD drawings are also uploaded onto the Slate. At this point, aluminum tags or vinyl stickers are printed with the Slate QR code and sent to the manufacturing team. The manufacturing team can now access all the predesign and design information by scanning the Slate QR tag.

As each piece of insulation makes it way through the production stages, every department scans and documents its production effort. Every time an asset is advanced to the next production stage, the Slate captures user information, along with a timestamp, as it’s advanced to the next stage. This gives complete visibility of every asset’s location within production. This visibility is not only available to the production team, but also any team member with access (Admin, Sales, Shipping, etc.).

Differentiation helps manufacturers sell more products, and Slates stay with assets that are eventually passed on to the end user. End users are able to perform detailed manufacturer-recommended inspections to ensure prolonged life of the assets.